HAVE ANY QUESTIONS? CLICK HERE

The Most Common Forklift Accidents

Forklift accidents are unpleasant occurrences that can happen in warehouse and transportation organizations, despite how practical and innovative forklift vehicles are.

Although there are many different forklift truck training programs available to reduce accidents in the warehouse, this doesn't completely eliminate the chance that a catastrophe will happen.

All of us are susceptible to human mistake, hence this essay will discuss:

Although there are many different forklift truck training programs available to reduce accidents in the warehouse, this doesn't completely eliminate the chance that a catastrophe will happen.

All of us are susceptible to human mistake, hence this essay will discuss:

- Most common forklift accidents

- Preventative measures

- Final considerations

It is commonly known that forklift trucks cause more significant workplace accidents than autos and heavy goods vehicles (HGV). Additionally, according to OEA 2021 statistics, forklift truck accidents result in 61,800 non-severe injuries and 34,900 serious injuries each year. What's more significant is that accidents can sometimes happen even when forklift trucks are handled safely, therefore it's critical to reduce the likelihood of accidents as much as you can to stop the increase in accident-related statistics.

In light of this, we have listed the most frequent forklift incidents below:

This means that it may cause the driver, as well as anyone nearby, serious injuries, furthermore, if your forklift drives over objects that have been left in your route, it could cause damage to the vehicle, create an imbalance which could lead to an accident.

In order to avoid any potential hazards for you and your forklift, always be sure to assess your surroundings and establish a strategy before operating a forklift truck.

For instance, if a heavy load needs to be stored on the top level of racking in the warehouse to conserve space but the forklift driver is distracted, the load could either fall onto onlookers or onto the forklift truck or it could clip other storage pallets, which could cause a chain reaction and knock off more pallets.

Forklift operators who are incompetent or unskilled may accidentally run over pedestrians because of lack spatial awareness, or they may collide with other cars because, for example, drivers are not using their rearview mirrors.

In order to increase your forklift handling and peripheral awareness, it is advised that you constantly exercise caution when operating a forklift truck in terms of speed and control.

With hundreds of incidents of forklift trucks being driven at too high speeds being reported each year, speeding is still one of the most frequent causes of disasters in warehouses.

In light of this, it is strongly urged that maximum speed zones be in plain view of all personnel using forklifts and that operators be able to recall the designated speed restriction when questioned.

Speeding and unbalanced truck loads can result in forklift truck accidents, as we've already mentioned. However, you may significantly reduce the amount of accident incidents that occur around the workplace by implementing regular and efficient training programs for your truck operators.

The likelihood of accidents happening around the workplace will be significantly reduced if you urge experienced operators who work in your warehouse to complete the refresher course to brush up on forklift operation.

In fact complacency, can and does contribute to a number of accidents every year, operators who have years of experience fall into bad habits, cut corners and do things they know very well they shouldn't simply down to their experience.

Asking the candidate about past incidents and how they overcame them can be a good way to gauge their honesty and perhaps the severity of the accident, from which you can determine whether or not they are appropriate for the position.

It is commonly known that weariness can result in:

In light of this, we have listed the most frequent forklift incidents below:

Falling Over

We have a forklift tip over to begin our roundup of frequent forklift truck mishaps. A forklift truck may lose its center of gravity and topple sideways (laterally) or forwards (longitudinally) if the load is too heavy or due to an uneven surface or unevenly loaded truck.This means that it may cause the driver, as well as anyone nearby, serious injuries, furthermore, if your forklift drives over objects that have been left in your route, it could cause damage to the vehicle, create an imbalance which could lead to an accident.

In order to avoid any potential hazards for you and your forklift, always be sure to assess your surroundings and establish a strategy before operating a forklift truck.

Racking Error

Forklift accidents, such as racking failures, have the potential to be fatal under the wrong conditions. Videos posted online frequently show entire warehouses being demolished due to catastrophic racking failure.For instance, if a heavy load needs to be stored on the top level of racking in the warehouse to conserve space but the forklift driver is distracted, the load could either fall onto onlookers or onto the forklift truck or it could clip other storage pallets, which could cause a chain reaction and knock off more pallets.

Vehicle/Pedestrian Collision

People and other vehicles are susceptible to collisions and are accustomed to serious mishaps, much like objects.Forklift operators who are incompetent or unskilled may accidentally run over pedestrians because of lack spatial awareness, or they may collide with other cars because, for example, drivers are not using their rearview mirrors.

In order to increase your forklift handling and peripheral awareness, it is advised that you constantly exercise caution when operating a forklift truck in terms of speed and control.

Speeding

Speeding is the final most frequent factor in forklift accidents that we have listed.With hundreds of incidents of forklift trucks being driven at too high speeds being reported each year, speeding is still one of the most frequent causes of disasters in warehouses.

In light of this, it is strongly urged that maximum speed zones be in plain view of all personnel using forklifts and that operators be able to recall the designated speed restriction when questioned.

Prevention Techniques

Now that the most frequent forklift truck accidents have been mentioned, it is time to be aware of the precautions that can prevent these accidents from happening in the first place. These precautions are described below:Training

The most important preventive strategy if you want accidents in the warehouse to be significantly decreased is training. Forklift accidents can actually be decreased by as much as 70% with proper training and awareness of the safety protocols.Speeding and unbalanced truck loads can result in forklift truck accidents, as we've already mentioned. However, you may significantly reduce the amount of accident incidents that occur around the workplace by implementing regular and efficient training programs for your truck operators.

The likelihood of accidents happening around the workplace will be significantly reduced if you urge experienced operators who work in your warehouse to complete the refresher course to brush up on forklift operation.

In fact complacency, can and does contribute to a number of accidents every year, operators who have years of experience fall into bad habits, cut corners and do things they know very well they shouldn't simply down to their experience.

Successful Employee Vetting

Verifying credentials and other relevant information about a job candidate is part of the employee screening process. One of the best methods to avoid forklift truck accidents is to ensure that any possible new hires have a stellar history of prior warehouse experience.Asking the candidate about past incidents and how they overcame them can be a good way to gauge their honesty and perhaps the severity of the accident, from which you can determine whether or not they are appropriate for the position.

Added Vacation Time

Giving personnel who are prone to forklift driver fatigue additional breaks is the final preventative strategy to lower workplace accidents. For those working in a warehouse setting, fatigue is a dangerous issue.It is commonly known that weariness can result in:

- Reduced ability to focus

- Irritability

- Aching or weakening in the muscles

- Dizziness

- No memory

- Difficulty concentrating

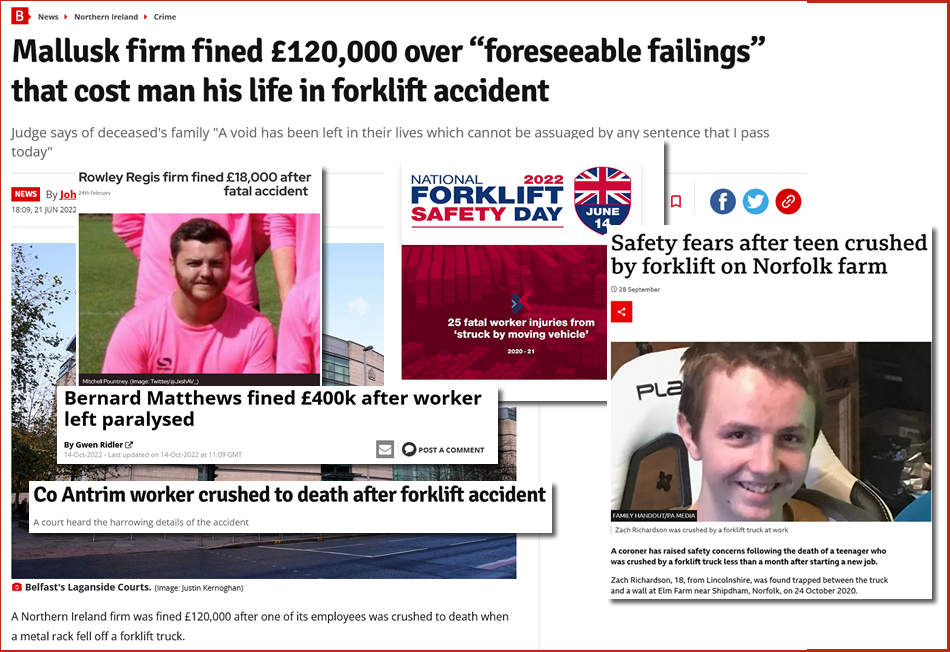

Training isn't cheap, but accidents don't just hurt people and destroy lives they can hurt businesses too, don't be the company that costs an employees life and is fined hundreds of thousands of pounds!

Customers usually find us by searching...

forklift licenses, forklift truck training, fork lifting course, forklift license cost, forklift license near me, fork lift truck training, forklift operator license, forklift driver training, fork lift truck licence, forklift driver license, forklift license course, counterbalance forklift training, fork truck training, forklift driver licence, course forklift driver, counterbalance forklift training near me, forklift license training, forklift license online, forklift driver certification, Reach Truck Training, VNA Training, Order picker Training, Man Up Training, Pallet Truck Training, Side Loader Training

RDW LIFT TRUCK & TRANSPORT TRAINING SERVICES